Table of Contents

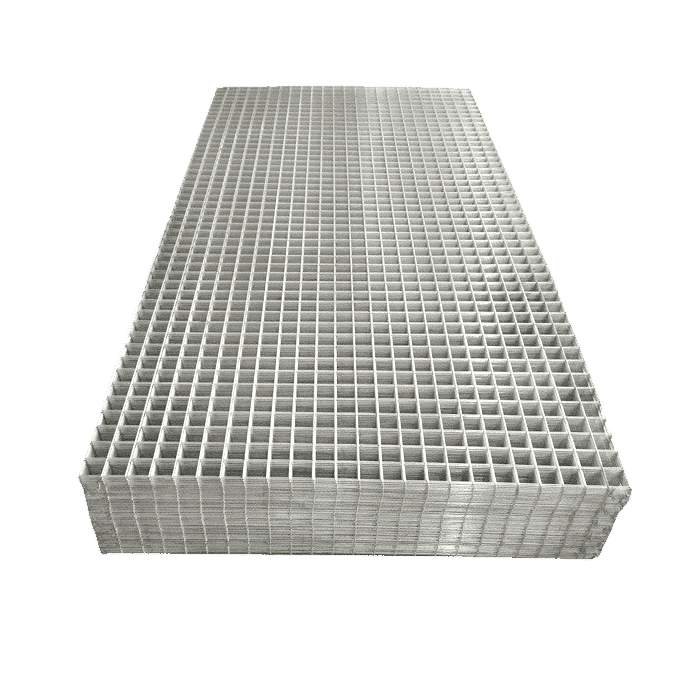

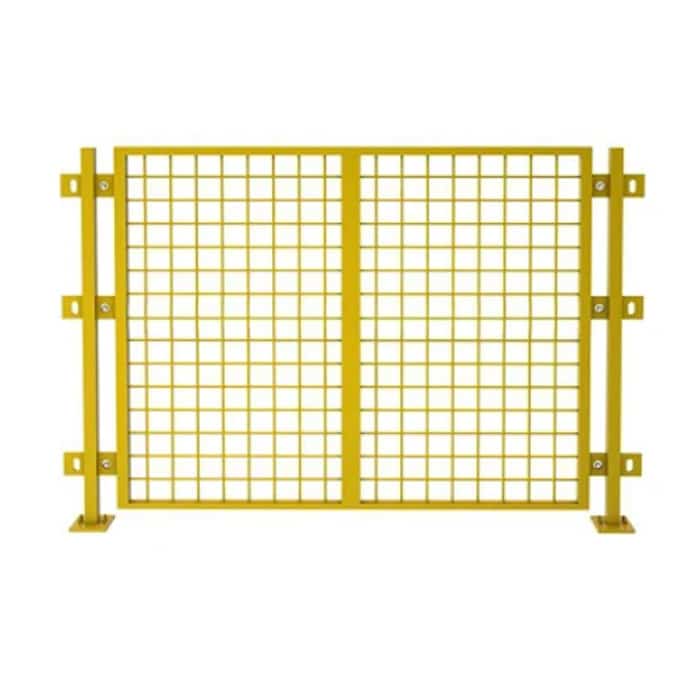

What Is A Welded Wire Fence?

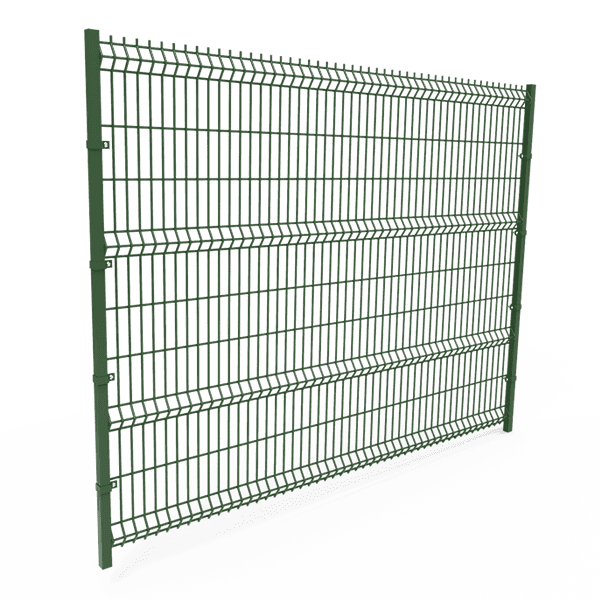

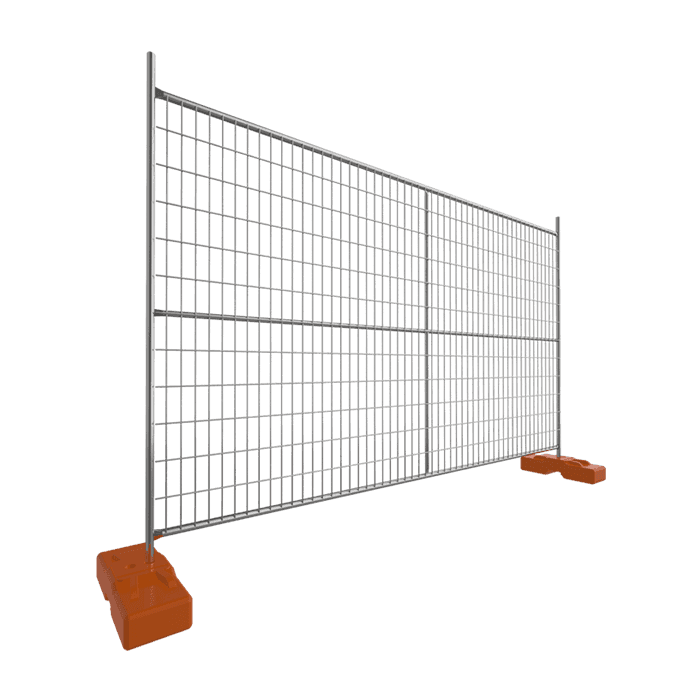

A homeowner, garden owner, farm owner or a simple landower has plenty of options today when it comes to securing their respective property against any intruders. But one very effective material they could readily use is what is called welded wire fence. One of the most popular materials used in construction, it comes in different sizes and thicknesses.

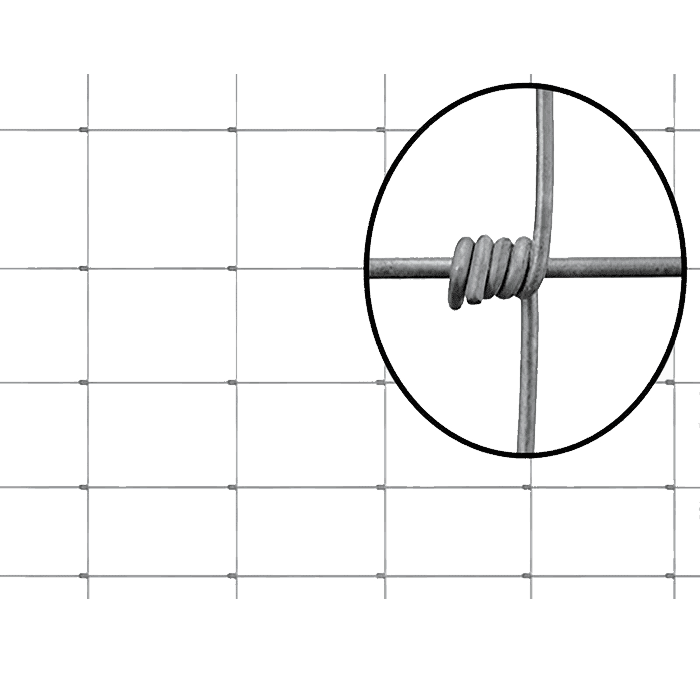

Also called utility fence because of its various relevance in construction works, while others refer to it as the general-purpose fence because of its wide application in fencing tasks, a welded wire fence or welded wire is made by welding the spot where the horizontal and vertical wires coincide. This process is otherwise called spot-welding. A quite tedious process, which makes the mesh firm and durable.

There are three types of welded wire fence in the market today, providing a tailored solution to any buyer, depending on their construction work. First one is PVC coated, which not only makes the wire colorful (depending on the PVC powder used) but also protects the wire from rust and erosion. Second is galvanized (sealing the wire with molten zinc to prevent corrosion in the future), while the third is stainless steel (the most expensive type).

The Correct Steps to Install Welded Wire Fence

Aside from the fact that a welded wire fence is durable and can resist weathering, installing it is easy. You can even do it on your own. It’s a quick and very effective solution to protect your property.

The Preparation of Materials

- Let’s start with measuring the property you want to fence. In the process, you want to know the total length of the fence you want to put up—how many meters or feet it should be. So that when you go to the shop to buy a welded wire fence, you already know the exact length that will be enough to fence the property.

- Decide on how many feet apart the posts will be. It could be 5 feet or 6 feet apart. Check to see which distance is most appropriate. Pick one that is not too loose or too tight upon installment.

- Depending on the height of the welded wire fence you are to purchase (i. e. 5 feet tall and 6 feet long), you also need to prepare the posts or the stakes that will serve as a guide to the fence mesh and put structure to the enclosure. There are different stakes available in your local shop, whether made out of steel or wood.

- Don’t forget to buy the other tools (i. e. garden post driver, plier, clamp) or accessories you need such as posts fasteners, zip ties and galvanized staples.

The Installation Process

- So now, you have all the materials you need. We’ll proceed to the installation. Before you install anything, marking the line where you want to put the fence is important. This way, the installation will be straight and organized. You can use a long tie or a blade tape measure to create a straight line.

- Using your blade tape measure, mark out the distance in between your posts or stakes. Again, it could be 4 feet, 5 feet or 6 feet apart, depending on how sturdy you want your fence to be.

- Once you are satisfied with the markings and lines you created, go ahead and put the posts. You can initially set the post by hand and then you can push it using the post driver. See to it that the post is buried at least 1 foot deep, same with the others so that they will all have the same height.

- Unroll the welded wire fence on the ground. Carefully stand it up into place on the first post while putting a clamp on the top most portion of the second post so that it won’t wobble. The rolls can be quite heavy especially if you are doing this alone so just do the steps one at a time, no rushing actions.

- Fasten the wire fence permanently on the post using the post fasteners, zip ties or the staples, depending on the post material you are using, whether steel or wood. Do this in each of the posts or stakes. You can use the clamp to resecure the fence while you are doing this.

- If ever you are working on an uneven terrain and you see a loose area on the fence, you can actually cut in between the mesh and tighten it again using a plier. It’s that easy.

Advantages and Disadvantages of Welded Wire Fence

Advantages:

Easy and Quick to Install

Who wants to work with a construction material that is difficult to install? No one, especially if you are doing it yourself. Welded wire fence should be your first option if you are looking for a fencing material to protect your home, garden, farm or a piece of land from any unwanted intruders. You’ll be surprised at how fast this fence can be installed too.

It won’t take up so much of your time, effort and energy. You prepare the roll of welded wire fence, the posts, do some markings and then attach the fence to the post carefully until you are done.

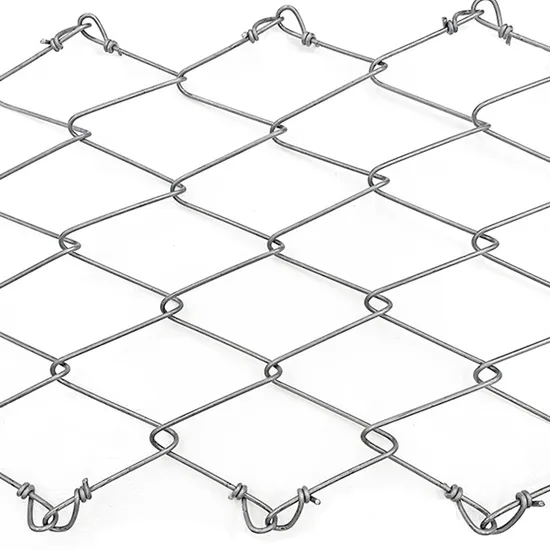

Cost Effective or Low-Cost Alternative

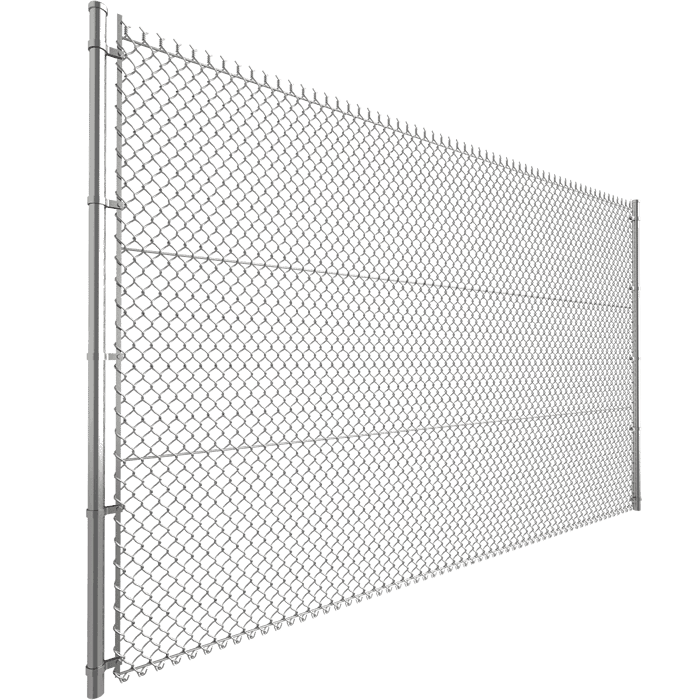

Compared to other fencing options such as chain link, welded wire fence is more affordable. It won’t take up so much of your budget. You’ll still have extra money then to finance the accessories needed for your home construction project.

Resist Weathering, Corrosion, Rust

Welded wire fence is durable. It can be PVC coated, galvanized or simply stainless steel. These types are known to resist weathering, wear and tear, corrosion or rust.

Variety of Application

Maintaining its structural integrity throughout its use, welded fences has been a choice for many homeowners when it comes to home improvements or simple home or property construction projects. Because of spot-welding, this fence is typically chosen for level ground runs.

Disadvantages:

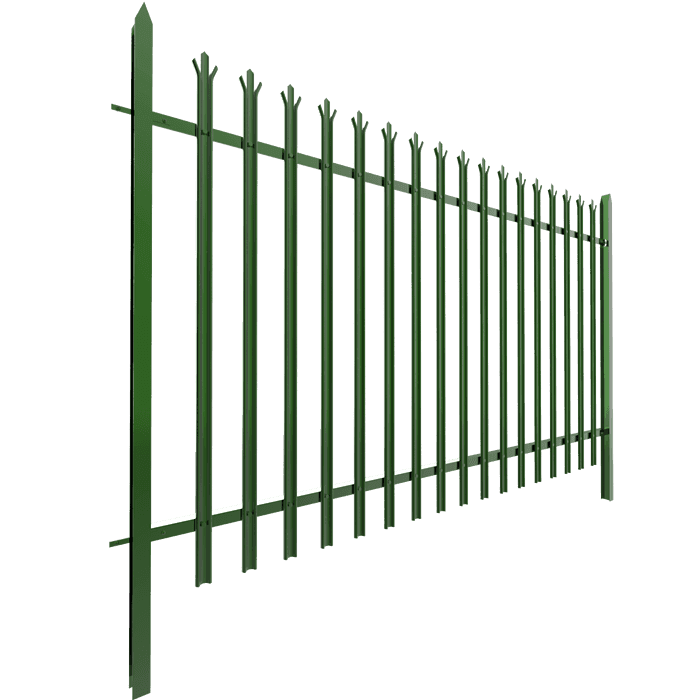

Compromised Privacy

The spacing between the horizontal and vertical wires creates an open design which can compromise the privacy of the owners. The people outside can see through it and the homeowner may need to put planting hedges. The privacy offered is limited so this type of fence is not a choice for some people especially those who are popular or have expensive properties to secure.

Increasing Cost

The cost of a welded wire fence also depends on the size and thickness of the material. The bigger or the taller and the thicker the wire fence, the more expensive it is. So, as a buyer, you must be aware of this increasing cost.

Challenging Installation

It can be very challenging to install welded wire fence on uneven terrain especially if the wire is big and thick. You may need assistance from someone to hold or set up the wire mesh on the posts or stakes in order to avoid any injury in the process. You have to be very careful since you are working with steel.

Compromised Security

Over time, when not properly maintained, a home, garden, farm or a land’s security can be compromised when using welded wire as a fence. The wire fence can develop weak spots or some areas may bend throughout time.

How Long Does Welded Wire Fence Last?

Who doesn’t want their investment on a welded wire fence to last a lifetime, right? But because of a variety of factors, this is impossible. There is a standard lifespan of each type of welded wire mesh. Generally though, with proper maintenance, welded wire fence can sustain from 5 years up to 15 years—a super worth it investment on securing your own property.

What are the factors that affect the lifespan of your welded wire fence? The process by which it is made (PVC coated or galvanized), the climate of the place in which it is put up (whether it is hot or dry, or with normal water or seawater interaction—these can cause corrosion or rust), how it is installed, and how it is maintained. Checking all of these factors as you install your welded wire fence can make your investment last.

How do you extend the lifespan of your welded wire fence? First and foremost, you have to choose the best material for the wire considering its size and thickness that is appropriate for securing your property.

Second, install the welded wire mesh with the correct instructions; don’t just do it immediately without reading guidelines.

Third, whenever you see dust forming, clean it as quickly as you can to prevent it from spreading to the other mesh.

Fourth, do a regular inspection of any damages and fix it accordingly.

Fifth, see to it that the wire does not come in direct contact with any soil, moisture or seawater.

Do You Have to Stretch Welded Wire Fence?

If you have used a welded wire fence for years, you’ve used it to enclose your garden or fence your orchard for extra security and protection, you already know the one tricky part of its installation—it does not stretch or compress. It is firm in its structural integrity. This means installing a welded wire fence to uneven ground can be a struggle since it does not adapt very well.

Welded wire does not change angles that easily, and if you try, the mesh will compress inside or outside instead, which can produce a bulge in an otherwise smooth looking mesh. One of the best ways you can avoid this is to level the ground along the fence line. You can also install the welded wire matching the point of elevation and just cut custom pieces to fill any possible gaps.

How To Repair Welded Wire Mesh?

If it can be repaired, then best to repair, in order to maximize your investment. Generally, there are a few tools you need to repair your welded wire fence including fence stretcher (puts tension, which makes the fence taut), fencing sleeve (connects wire fence), plier and glove. While these tools are essential in repairing the fence, there might be instances where you might need other extra tools or equipment such as when a significant portion of wire is missing or has been damaged.

Once you have all the necessary tools, you have to start repairing as soon as possible. Otherwise, the security and protection of your property will be compromised. No worries because this task does not require a whole day of work.

First, check the damages and assess each one of them. Then choose one where you will start, clear the area and have near you the tools.

Second, locate the splitting of wires and use the fence stretcher to pull each of them inwards to be taut again.

Third, use the fencing sleeve to reconnect the two sides.

Fourth, if you see strands of wire hanging out, separate and wrap them around the wire to make the fence more secure.

In case the damage is too much that it can’t be repaired but be replaced, then go ahead replace the damaged section. However, you need to put more sleeves on the fence. Also, make sure that the fence stretcher is working perfectly since you need this in this process significantly.

Conclusion

A welded wire fence is a great option to secure and protect your property. It is cost-effective, easy to install, low maintenance, an effective rigid enclosure, used in different applications, and long lasting. There are several types you can choose from—PVC coated, galvanized or stainless steel.

Although it can be challenging to install in an uneven ground, it can easily be solved with proper ground leveling and using tools such as fence stretchers to become taut when installed. Repairing damages does not require a whole team but can be done solo or do it yourself. Also, welded wire fence repair tools are always available in the market for easy access.

Secure your property with a welded wire fence now!